Laser marking delivers precise results when labeling materials

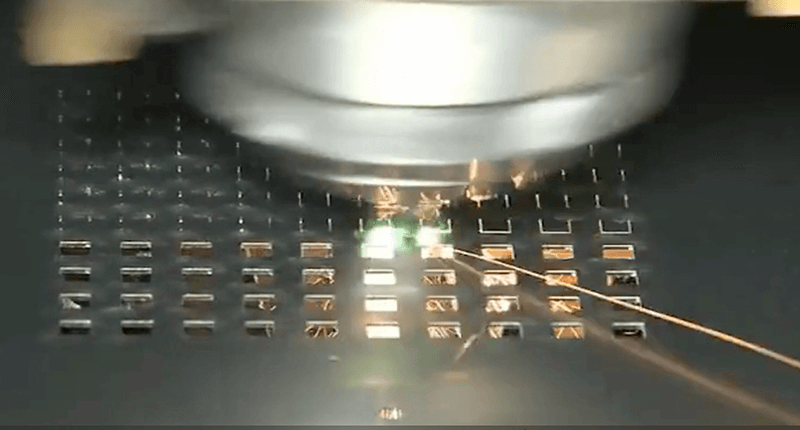

Laser marking is a process for permanently marking materials and surfaces using a Laser. This process is used in various industries and applications to mark, personalize, track or apply information to products.

Advantages of Laser marking

Laser marking, also known as Laser labeling, is a versatile technology that plays an important role in many industries and applications. It enables the identification, tracking and personalization of products and has a wide range of applications in modern manufacturing and marking.

Flexibility

Laser labeling can be applied to almost all materials.

Speed

Laser marking is a fast marking method. The Laser beams work in fractions of a second, which enables a high production speed.

Durability

Deep engraving enables markings to be permanently retained on the component. This even applies if they are subsequently painted.

Precision

Laser marking enables extremely precise markings and engravings. Even fine texts, barcodes and complicated graphics can be applied with high accuracy.

How does Innotech Laser support you with Laser labeling/ Laser marking?

Selecting the right Laser system components determines the success and efficiency of Laser marking. With the help of the Laser components we have defined, you can achieve the Laser marking you want for your production.

Here are some key aspects that the consultants at Innotech Laser can help you with when selecting Laser components for successful Laser marking.

Advantages:

- First-class advice on the selection of Laser components

- Customized combination from the large selection of components

- High-quality Laser products for flexible integration

- Technical support and maintenance of our products

"Almost anyone can produce Laser marking systems these days. With the help of our products, you can remain competitive and deliver outstanding quality at an attractive price-performance ratio."

Maximilian Abeln, Innotech Laser GmbH

Typical applications in Laser labeling

Labeling of metals

Marking metallic components with Lasern is a common process in various industries to permanently mark or label components or workpieces. These markings are often used to apply information such as serial numbers, barcodes, logos, dates, manufacturer information and other relevant data to the components.

Most frequently selected configuration for marking metallic components Laser

Raycus Q-Switched fiberlaser RFL-P30QB

Galvo scanner innoSCAN II-10

Laser Optics F-Theta 1064 nm

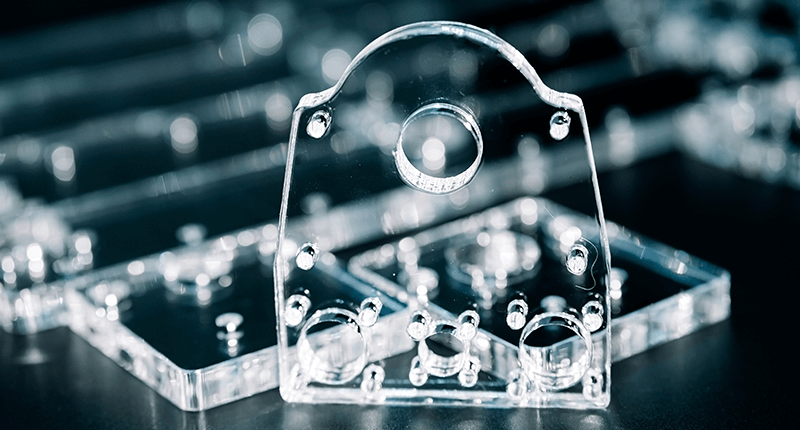

Labeling of plastics

Plastics can be processed with Lasers to apply markings and engravings that are often used in the manufacture of packaging and plastic products. Of course, you need different Laserparameters for this than for marking metals. We will be happy to help you select the correct parameters.

Most frequently selected configuration for marking plastics

Raycus MOPA fiberlaser RFL-P30MX

Galvo scanner innoSCAN II-10

Laser Optics F-Theta 1064 nm

Labeling glass and ceramics

Laser marking of glass and ceramics is a powerful technology that is used in various industries to mark and personalize these materials. It offers precision, durability and versatility in the manufacture and design of products.

Most selected configuration for marking glass and ceramics

Raycus MOPA fiberlaser RFL-P70MX

Galvo scanner innoSCAN II-12

Laser Optics F-Theta 1064 nm

Let us advise you and test for yourself

If you have any questions, need a quote or would like to test a configuration in our technical center, please send us an e-mail or simply give us a call. We will answer you as quickly as possible.

Contact us

Address

Innotech Laser GmbH

Giesenheide 31

40724 Hilden

Germany

Office hours

Monday to Thursday

08:30 am to 5:00 pm

Friday

08:30 am to 4:00 pm

Further applications

Glass laser treatment

The Laser treatment of glass surfaces is an application for which Laser systems are made: They create patterns, smooth or clean the surface as required.

Laser cuttiung

Laser systems are tools that are low-wear and versatile. They are therefore used in almost all industries for cutting materials, hard or soft.

Learn more about laser cutting

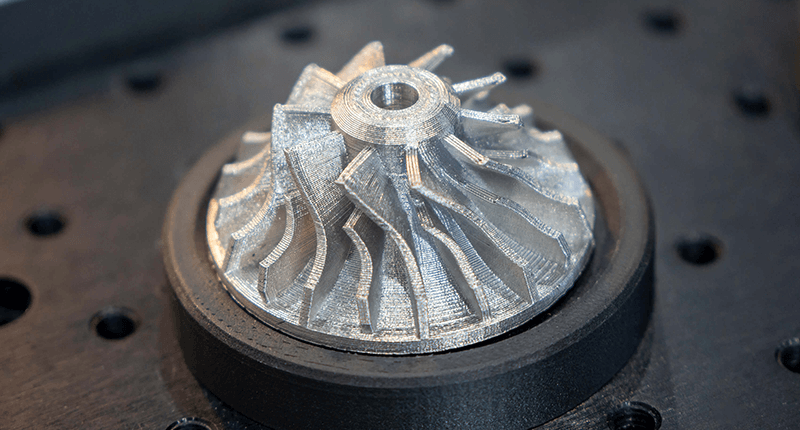

Metal 3D printing

Laser Additive manufacturing, or Laser-based 3D printing, is a revolutionary manufacturing technology for creating prototypes and sample parts.